Manufacturing & Assembly

Our approach

OP Machine’s equipment line up and depth of experience allows us the flexibility to offer our customers a total manufacturing package. Our ability to control all aspects of the production process is key to providing 100% conformance to our customer specifications. OP Machine’s registration with the ISO 9001:2018 quality management system insures your parts are made to the highest standard with full accountability at all processing steps.

Assembly

Complementing our production facility is a fully serviced assembly department where knowledgeable staff can bring all manufactured parts together for a seamless integration into a finished product. Backed by our strong quality assurance program we can ensure assemblies are built to exacting customer specifications with the ability to identify issues and devise solutions as they are detected. This value added service is ideal for customers who wish to streamline their manufacturing needs, lower their overall production costs, and eliminate unnecessary handling between production stages.

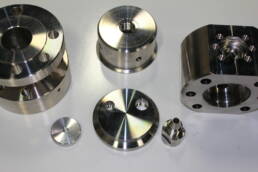

Milling

Our CNC milling department is the cornerstone in OP Machine’s multifaceted production services. These machines can perform many labor intensive operations with extreme accuracy and consistency, producing quality parts in both production and prototype size lots. Three complete machine centers, two having high capacity tool holders, allows us to accommodate various jobs quickly and efficiently without the need for full tear down and re-setup making time sensitive jobs affordable while having less impact on scheduled work. Fourth axis milling capabilities further reduce manufacturing costs and lead times with fewer setups and operations for complex features.

- Specifications

- Maximum XYZ travels 50″x20″x25″

- Maximum Table Size 52″x18″

- Programmable Fourth axis machining

Turning

OP Machine employs both CNC (Computerized Numerical Control) and manual turning equipment enabling us to accommodate a wide array of customer requirements. Large and small production runs are supported by a bar feed system, giving shorter lead times and greater cost effectiveness. Live tooling adds to our CNC Lathes versatility by reducing the number of operations needed for more complex geometries. With the recent addition of a new CNC turning center, our lathe capacity has doubled further reducing part lead time. This now enables us to offer quick turnaround solutions for time sensitive parts where precision, quality, and good value are paramount.

- Specifications

- Maximum cutting diameter 21″

- Maximum cutting length 26″

- Spindle Bore 3″

- Live tooling

Quality Assurance

OP Machine is currently certified and registered with the ISO 9001:2015 quality management system standard. This system was implemented to better support the requirements of our customers, to ensure a quality product, and to provide a system of continuous improvement for the management of the company. Quality checks are performed throughout the manufacturing process from raw material inspections, first article reviews, and final part analysis, all with supporting documentation guaranteeing traceability and accountability.

Regular non-conformance analysis, preventive and corrective action programs, and internal and external audits add to the system’s effectiveness, highlighting areas of improvement and reinforcing quality objectives.

OP Machine boasts a low part return/rework rate while maintaining exceptional on-time delivery often meeting or beating our customer’s delivery requirements. A strong quality program is key to providing this high level of service and it is OP Machine’s philosophy to continue striving for excellence and exceed our customer’s expectations.

Welding & Fabrication

Providing conventional welding operations such as TIG and MIG on both ferrous and nonferrous material, our welding and fabrication department add to OP Machines full service ability in providing support for repair work, part modification, and assembly.

Miscellaneous

- Brake Press

- Hydraulic 20 Tonne Press

Finishing Services

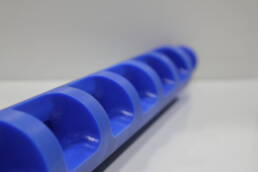

OP Machine is able to offer a host of high quality finishing options through various in-house techniques and industry partnerships.

-

Services Include:

- Deburring/Tumbling

- Heat Treating

- Powder coating

- Anodizing