Development & Design

Our approach

At OP Machine, we offer a variety of development and design services that provide our customers with more value added solutions. The design team at OP Machine can help take concepts through the development stages while maintaining focus on effective manufacturing steps. Having the capacity to produce a working prototype, we can identify and resolve design issues promptly, saving cost and time.

Having extensive knowledge in the manufacturing sector, we can breath new life into older designs by supplying cost effective replacement parts or using our experience to redesign a dated or inefficient system. We can reverse engineer most parts of small to medium size with exacting precision, creating drawings and providing manufacturing support for replication. Whether you require CAD modeling, reverse engineering, prototype development, or design troubleshooting, OP Machine can provide a solution.

Prototyping

Our talented design and manufacturing teams are dedicated to working closely with our customers to address requirements and provide assistance from the concept level through to product realization. As we develop first generation parts, we maintain focus on design intent, precision, and cost effectiveness using the latest manufacturing methods and tools. Design concepts can be analyzed before production using the latest CAD software to ensure the highest quality production in the shortest amount of time. Simple parts or complex systems, OP Machine’s ability to provide a full design and manufacturing facility simplifies the prototyping process, allowing for a seamless transition of our customer’s design concept to manufactured parts.

Reverse Engineering

For parts that are worn, broken, obsolete, or hard to replace, OP Machine can provide reverse engineering services to fit most applications. OP Machine utilizes both conventional and high tech shop measurement tools to determine the dimensions of a sample part. Tolerances and fits are calculated to applicable standards and reviewed by OP Machine’s technical staff. A detailed CAD drawing is developed from the collected data which can then be used in re-manufacturing the part.

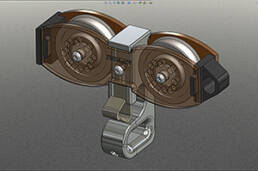

3D Modeling

OP Machine offers full service design and drafting capabilities utilizing the latest in 3D CAD software. Individual parts up to multilevel assemblies can be created in 3D allowing design intent and part integration to be analyzed prior to manufacturing. The versatility of accepting most CAD file types gives OP Machine the ability to create exacting precision and efficiency from initial estimating, to layout and design, and the development of appropriate manufacturing processes. Fully dimensioned drawings are developed for production and can be made available upon customer request.

Our preferred methods in providing 3D Modeling services are supported by SolidWorks and GibbsCAM.